E-postformatfeil

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

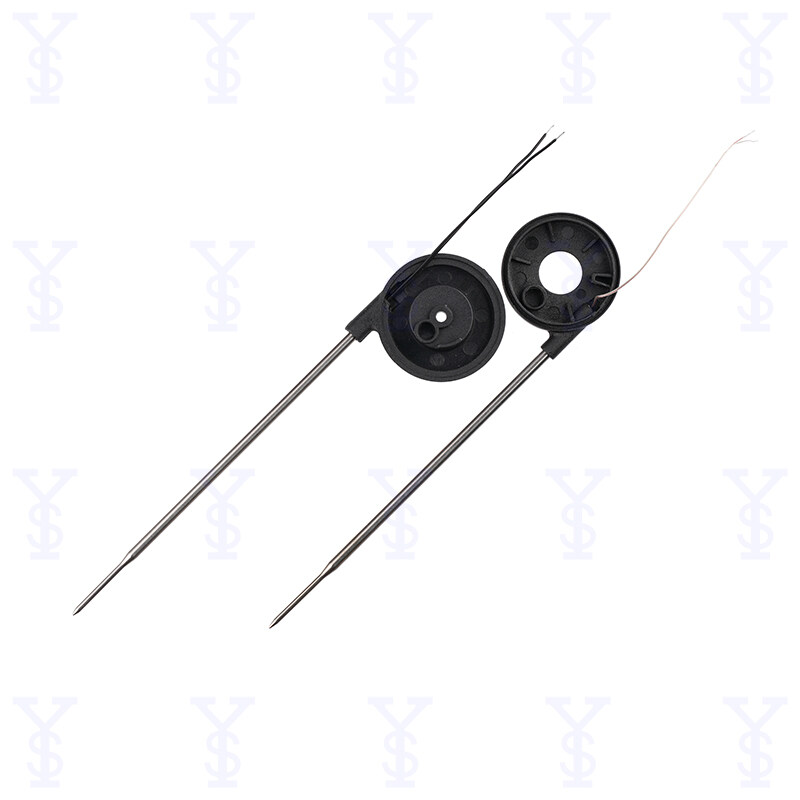

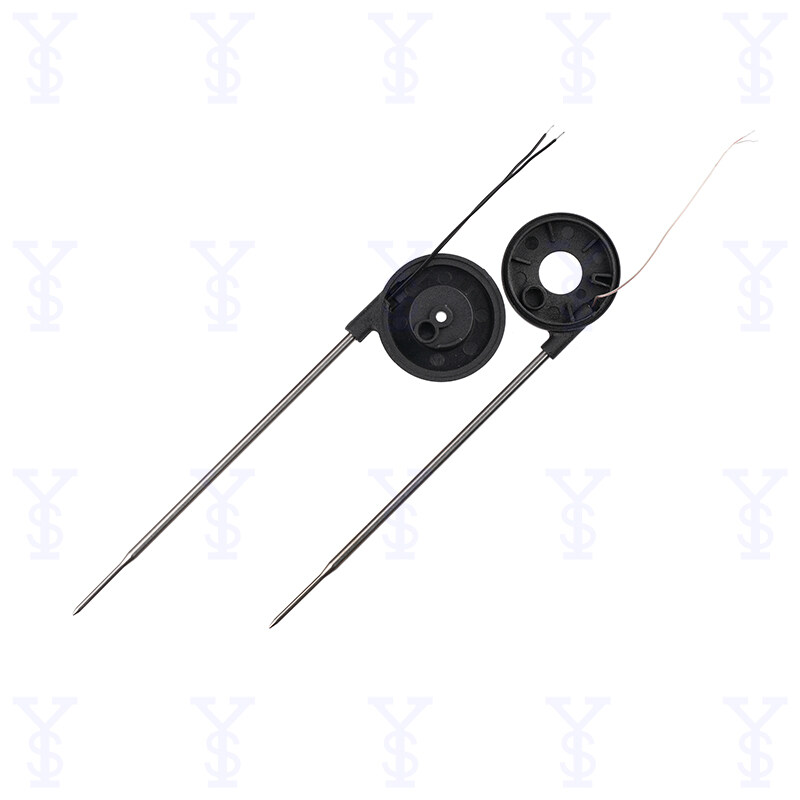

Demystifying Types of Thermocouple Temperature Sensors: A Comprehensive Guide

Thermocouples are ubiquitous temperature sensors known for their versatility and reliability in a wide range of industries and applications. Understanding the different types of thermocouples available is essential for selecting the right sensor for your specific needs. In this comprehensive guide, we will explore the various types of thermocouple temperature sensors, their characteristics, applications, and advantages.

1. The Basics of Thermocouple Temperature Sensors

Before diving into the different types of thermocouples, let's first understand how these sensors work and why they are so widely used:

- Principle of Operation: Thermocouples operate on the principle of the Seebeck effect, where a temperature difference between two dissimilar metals generates a voltage proportional to the temperature gradient. This voltage can be measured and correlated to the temperature being sensed.

- Advantages: Thermocouples are known for their wide temperature range, fast response times, and rugged construction, making them suitable for harsh environments and high-temperature applications.

2. Understanding Types of Thermocouple Temperature Sensor

Thermocouples are classified into different types based on the combination of metals used in their construction. Each type has its own temperature range, sensitivity, and characteristics:

- Type K Thermocouple: Composed of chromel (nickel-chromium alloy) and alumel (nickel-aluminum alloy), type K thermocouples are among the most commonly used thermocouples due to their wide temperature range (-200°C to 1260°C), high sensitivity, and relatively low cost.

- TypeJ Thermocouple: Made from iron and constantan (copper-nickel alloy), type J thermocouples offer good accuracy and stability in the range of -40°C to 750°C. They are commonly used in low-temperature applications where oxidation of the iron is not a concern.

- Type T Thermocouple: Constructed of copper and constantan, type T thermocouples are known for their excellent accuracy and stability in the range of -200°C to 350°C. They are often used in cryogenic applications and laboratory settings.

- Type E Thermocouple: Comprising chromel and constantan, type E thermocouples exhibit high accuracy and stability in the range of -270°C to 900°C. They are particularly well-suited for low-temperature measurements and applications involving extreme temperature cycling.

- Type N Thermocouple: Made from nicrosil (nickel-chromium-silicon alloy) and nisil (nickel-silicon alloy), type N thermocouples offer high accuracy and stability in the range of -200°C to 1300°C. They are ideal for applications requiring resistance to oxidation and high temperatures.

3. Applications of Thermocouple Temperature Sensors

Thermocouples find widespread use in various industries and applications due to their versatility and reliability:

- Industrial Heating and Furnaces: Thermocouples are commonly used for temperature measurement and control in industrial heating processes, such as heat treating, forging, and annealing.

- HVAC and Refrigeration: Thermocouples are employed in HVAC systems and refrigeration units for monitoring temperatures in air conditioning units, refrigerators, freezers, and chillers.

- Automotive and Aerospace: Thermocouples are utilized in automotive engines, exhaust systems, and aerospace applications for measuring temperatures in combustion chambers, exhaust gases, and critical engine components.

- Food Processing: Thermocouples are essential for temperature monitoring and control in food processing applications, including ovens, grills, deep fryers, and refrigeration units.

4. Advantages and Limitations of Thermocouple Temperature Sensors

While thermocouples offer many advantages, they also have certain limitations that should be considered:

- Advantages: Wide temperature range, fast response times, rugged construction, suitability for high-temperature and harsh environments.

- Limitations: Nonlinearity, susceptibility to drift over time, lower accuracy compared to some other temperature sensors (e.g., RTDs), requirement for calibration.

5. Factors to Consider When Choosing a Thermocouple

When selecting a thermocouple for your application, several factors should be taken into account:

- Temperature Range: Ensure that the thermocouple's temperature range matches the requirements of your application.

- Accuracy: Consider the required level of accuracy and stability for your measurements.

- Chemical Compatibility: Choose a thermocouple that is compatible with the chemicals and environments present in your application.

- Cost: Evaluate the cost of the thermocouple sensor and its overall value proposition for your specific application.

6. Maintenance and Care of Thermocouple Temperature Sensors

To ensure optimal performance and longevity of thermocouple temperature sensors, proper maintenance and care are essential:

- Regular Calibration: Periodic calibration is necessary to maintain the accuracy and reliability of thermocouple measurements.

- Protection from Contamination: Protect thermocouple wires and junctions from contamination by chemicals, moisture, and corrosive substances.

- Inspect for Damage: Regularly inspect thermocouple wires and connections for signs of wear, corrosion, or damage, and replace any damaged components promptly.

Conclusion: Choosing the Right Thermocouple for Your Application

Thermocouples are versatile temperature sensors that find wide use in diverse industries and applications. By understanding the different types of thermocouple temperature sensors available, their characteristics, advantages, and limitations, you can select the right sensor to meet the specific requirements of your application. Whether it's monitoring temperatures in industrial processes, HVAC systems, automotive engines, or food processing equipment, thermocouples offer reliable and cost-effective solutions for temperature measurement and control.